Well, it's finally delivered, set up, running, and ready to go. If I may say so, it totally rocks.

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| My New Baby (finally) http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=6601 |

Page 1 of 2 |

| Author: | John Watkins [ Tue May 09, 2006 6:36 am ] |

| Post subject: | |

Well, it's finally delivered, set up, running, and ready to go. If I may say so, it totally rocks.

|

|

| Author: | JJ Donohue [ Tue May 09, 2006 6:42 am ] |

| Post subject: | |

Congratulations, John. It looks impressive. Can't wait to see the chips flying from those necks...send some action pics if you can! |

|

| Author: | Pwoolson [ Tue May 09, 2006 7:01 am ] |

| Post subject: | |

Are those handles on the front so you can pick it up and move it around the shop?

Great news! I look forward to seeing what it produces. Show lots of pics. |

|

| Author: | John Watkins [ Tue May 09, 2006 7:03 am ] |

| Post subject: | |

Actually, that's exactly what they are (smart ****).

Perfect size and spacing for a forklift. |

|

| Author: | Sprockett [ Tue May 09, 2006 7:15 am ] |

| Post subject: | |

I'm not going to show any pictures of mine when it gets here now, that's just too cool and this will just make mine look like a tinker toy

I see you did the keyboard/monitor combo arm, I'm doing essentially the same thing with mine. Mine's quite a bit smaller though

I'd love to see some video of it in action... Good Job Man!! -Paul- |

|

| Author: | Don Williams [ Tue May 09, 2006 7:25 am ] |

| Post subject: | |

Is there such a thing as CNC envy? |

|

| Author: | Pwoolson [ Tue May 09, 2006 7:48 am ] |

| Post subject: | |

[QUOTE=John Watkins] Actually, that's exactly what they are (smart ****).

Perfect size and spacing for a forklift. [/QUOTE] Indeed, but I forgot that you had a forklift hitten in your spray booth. Just don't call me when you decide you want it on the other side of the shop. I have to wash my hair that day. |

|

| Author: | John Watkins [ Tue May 09, 2006 7:50 am ] |

| Post subject: | |

Don't worry. You weigh even less than I do. You're safe. By the way, they horizontal members are SOLID 3" square tube, not tubular. I still hurt. I shopped far and wide for that arm and had almost decided to just make one when I stumbled on it. They are ridiculously priced for a new one (this one is $850 new) because they are for the health care industry. There will be video soon, and I, for one, definitely want to see your machine when you get it. It's not a contest!  |

|

| Author: | Sprockett [ Tue May 09, 2006 8:52 am ] |

| Post subject: | |

Yeah prices on things like that are just stupid, I found one for cheaper by digging around but it's still $350 which is just outrageous. I'm debating on building a full hood for mine to hold in the noise and dust, the guy from K2 sent me a picture of his and he has a whole box around it with doors to get access. I'm not as much worried about dust as I am noise.... I'll post some pics when it gets here, I have all the software and the computer already so I have lead up time to play, we figure about 4 more weeks and it should be ready to go... -Paul- |

|

| Author: | Don Williams [ Tue May 09, 2006 10:27 am ] |

| Post subject: | |

I helped a friend move a cnc just like that last year. That is, myself and around 8 or 9 other guys. We had to get it down a hill to the back of his house and into the basement shop. What a nasty chore that was. Tom Dowey and Craig Sullivan were there and can attest to how heavy those things are. Great looking machine...wish I had room for one. |

|

| Author: | Bob Garrish [ Tue May 09, 2006 12:59 pm ] |

| Post subject: | |

I'd love to talk to you about how you find the machine once you've had it for a couple weeks. I'm looking at getting essentially the same machine (4896 because I'll have the room for it by the time I can get it) but there's not a whole lot of info out there, even from Techno, about how it performs on hardwoods and what sort of feeds/speeds to use with tooling. |

|

| Author: | Rand Kennedy [ Wed May 10, 2006 1:00 am ] |

| Post subject: | |

Very nice ! |

|

| Author: | Tom Dowey [ Thu May 11, 2006 12:20 am ] |

| Post subject: | |

Very nice John. And Don is right, those things are heavy. |

|

| Author: | John Watkins [ Thu May 11, 2006 10:18 pm ] |

| Post subject: | |

Thanks, guys. Bob, I'd be happy to talk to you about it and answer whatever questions as I'm able. I can tell you that it will air cut a Strat profile at 1000 ipm which takes about 6.5 seconds.

|

|

| Author: | Bob Garrish [ Tue May 16, 2006 2:22 pm ] |

| Post subject: | |

Alright, John, you've had your week. Let's hear the juicy review and maybe see some CNC action shots  |

|

| Author: | KevinA [ Wed May 17, 2006 12:36 am ] |

| Post subject: | |

WOW! Envy is right. Hon, I'm going to need a bigger shop!!!!!! Kevin |

|

| Author: | John Watkins [ Thu May 18, 2006 5:51 am ] |

| Post subject: | |

Well, I don't have any action pics yet because I've been scrambling to catch up and just haven't taken the time to snap any, but I will soon. In terms of a review, the thing is just unbelievable. I haven't really pushed the limits yet, but I have made 3/4" buried cuts in maple with a 1/2" cutter in a single pass at 400 ipm with no visible or audible strain for the machine. The finish is comparable to what you get out of brand new jointer knives. We'll see what the top end (failure speed) is when it's time to cut some of MY wood.

|

|

| Author: | KenMcKay [ Thu May 18, 2006 8:55 am ] |

| Post subject: | |

Put it on 11 John! |

|

| Author: | Bob Garrish [ Thu May 18, 2006 10:56 am ] |

| Post subject: | |

What sort of spindle do you have in that machine? And how do you find the Techno controller on 3D stuff? The spindle HP (along with table rigidity) are what's really going to hold back your top speed, I think. I'm wondering about the controller as I'm told they used to be poor once you were fully into 3D but this was from a few-years-old machine so they might have updated it. |

|

| Author: | John Watkins [ Thu May 18, 2006 9:57 pm ] |

| Post subject: | |

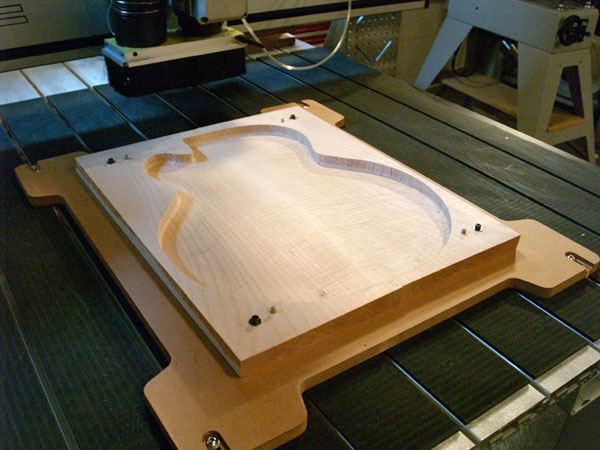

It's a Colombo 3HP. I think the speed limitation in most cases will be the hold-down strength and the strength of the material being cut. I'll be better able to comment on this once I get an ammeter installed on the spindle. The 3D look ahead on the techno control is the best I've seen, and I think I've tried just about all of the PC based ones. I forgot to interpolate arcs on one job before posting it and I didn't even notice at first. It appears to move in a single motion between stepovers. I don't think I'm doing it justice with this description so I'll just have to take some movies. Meanwhile, here's a crude picture.  |

|

| Author: | Sprockett [ Fri May 19, 2006 4:13 am ] |

| Post subject: | |

I like your clamping jig, I've been thinking about how to hold things like rosettes and bridges and little things.. Not sure if I want to use vaccum or mechanical, on some of these issues with CNC your kind of on your own!!

How long did it take to cut that? Good Stuff, I'm super impressed... I've only figured out how to make molds so far in Rhino!!

-Paul- |

|

| Author: | John Watkins [ Fri May 19, 2006 9:55 am ] |

| Post subject: | |

Thanks, Paul. There's no one solution to the hold-down problem. I problem use a 50/50 mix of vacuum and mechanical means. That top took a little over an hour, but I could probably cut that in half without really pushing it. We'll see. |

|

| Author: | Bob Garrish [ Mon May 22, 2006 9:37 am ] |

| Post subject: | |

I can't see if there's an ATC rack on the back there or anything, but what kinds of cutter(s) do you find work well for carving the maple tops? 0.5" ball end carbide? |

|

| Author: | John Watkins [ Tue May 23, 2006 11:10 pm ] |

| Post subject: | |

Bob, there's no ATC. I use round nose up-spiral carbide cutters as big as I can for the part. I've never tried ball-ends or other styles, so I'm no expert by any means. This works well for me, though. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|